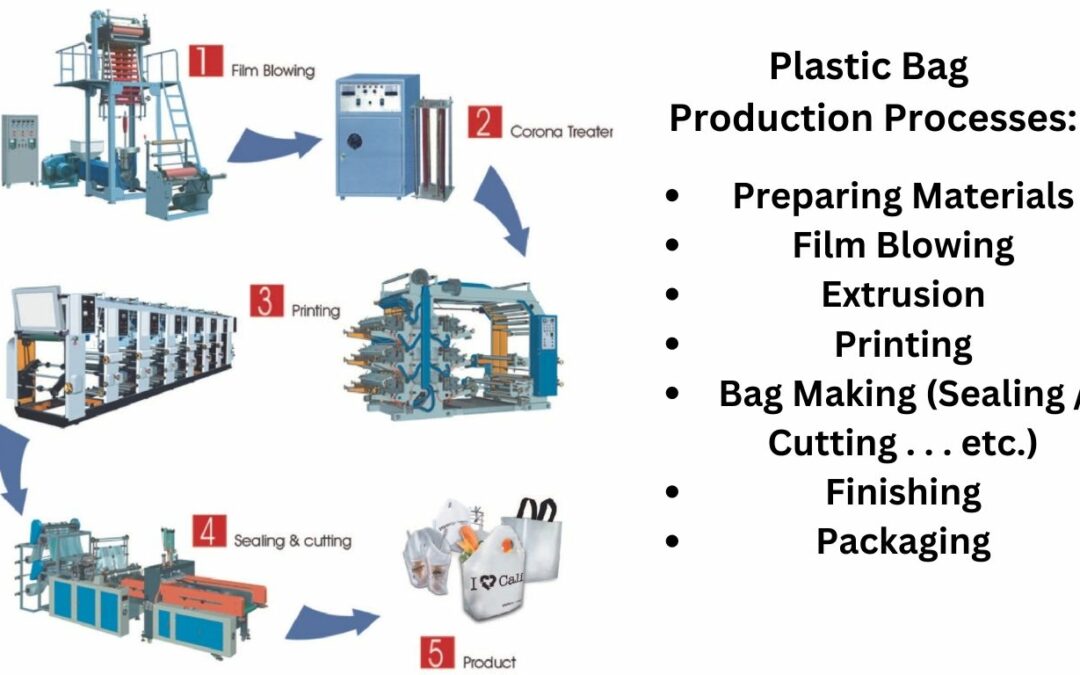

Plastic bag production typically involves several processes and stages, which may vary slightly depending on the specific type of bag being produced. Here is a general overview of the standard processes and stages involved in plastic bag production:

Before starting out the actual production process, there is a preparation stage which is material preparation. This is the very first thing a factory needs to do in plastic bag production. The preparation of the raw materials is basically the preparation stage for film blowing. The process usually involves melting down plastic pellets or flakes and mixing them with any additives or colorants that are needed.

1. Film Blowing: The film blowing process is commonly used in the production of plastic bags. The process involves melting down plastic pellets or flakes, extruding the plastic through a die to create a tube, cooling the tube, blowing air into the tube to form a bubble, controlling the size and shape of the bubble using rollers, and finally cutting and flattening the plastic film to create bags. Film blowing is an efficient and versatile method that allows for the creation of bags in a wide range of sizes and shapes, and can be used with various types of plastic materials.

2. Extrusion: The next stage is extrusion, where the molten plastic is forced through a die to create a long, continuous tube of plastic. The thickness and width of the tube can be adjusted based on the desired bag size and shape.

3. Printing: If the bags are going to be printed with a design or logo, this stage involves printing onto the plastic film before it is cut and sealed. This can be done using various printing methods such as flexographic, gravure, or digital printing.

4. Bag Making: In this stage, the tube of plastic is cut and sealed into individual bags using a bag-making machine. The bags can be sealed with heat, adhesive, or ultrasonic welding, cut into requested size and shape, depending on the type of bag and its intended use.

5. Finishing: The final stage involves finishing the bags by trimming any excess plastic, adding handles or other features, and packaging them for distribution.

Overall, plastic bag production requires specialized equipment, skilled operators, and adherence to safety protocols to ensure a high-quality and safe product.